Restaurant Point of Sale IoT Integration: Connecting Kitchen Equipment for Predictive Maintenance

5 minute read

Restaurant Point of Sale IoT Integration: Connecting Kitchen Equipment for Predictive Maintenance

Article at a Glance:

- Integration of IoT sensors with Point of Sale (POS) systems enables restaurants to monitor equipment performance in real-time, detect potential issues early, and optimize maintenance scheduling based on actual usage patterns.

- The system architecture requires three key layers: edge computing for local data processing, central processing for data management, and a user-friendly interface layer for staff interaction.

- Data-driven maintenance planning helps restaurants move beyond fixed schedules, incorporating equipment condition indicators, historical patterns, and operational schedules to optimize maintenance timing.

- For multi-location restaurant groups, IoT-POS integration offers centralized monitoring capabilities, enabling cross-location performance comparison and more efficient resource allocation.

- Successful implementation requires careful attention to technical infrastructure, security considerations, and a phased approach starting with pilot locations.

This integration represents a significant advancement in restaurant equipment maintenance, though success depends on careful planning, realistic expectations, and consistent execution rather than implementing technology for its own sake.

Equipment downtime in restaurants creates cascading problems that extend far beyond repair costs. When critical kitchen equipment fails during peak service hours, it disrupts operations, damages customer experience, and can harm a restaurant’s reputation. For multi-location restaurant groups implementing Point of Sale for restaurants, these challenges multiply across sites, making equipment maintenance a complex operational imperative.

Modern restaurant operations are exploring data-driven approaches to maintenance through the integration of Internet of Things (IoT) sensors with Point of Sale (POS) systems. This integration enables restaurants to monitor equipment performance, detect potential issues early, and optimize maintenance scheduling based on actual usage patterns and equipment condition. While the technology shows promise, successful implementation requires careful planning, realistic expectations, and consideration of various factors that can impact outcomes.

Understanding IoT Integration in Restaurant POS Systems

The foundation of data-driven maintenance combines equipment performance data from IoT sensors with operational insights from POS for restaurants. This integration provides a contextualized view of equipment behavior within actual business activity patterns, though the effectiveness depends heavily on proper system setup and data interpretation.

Equipment Monitoring Fundamentals

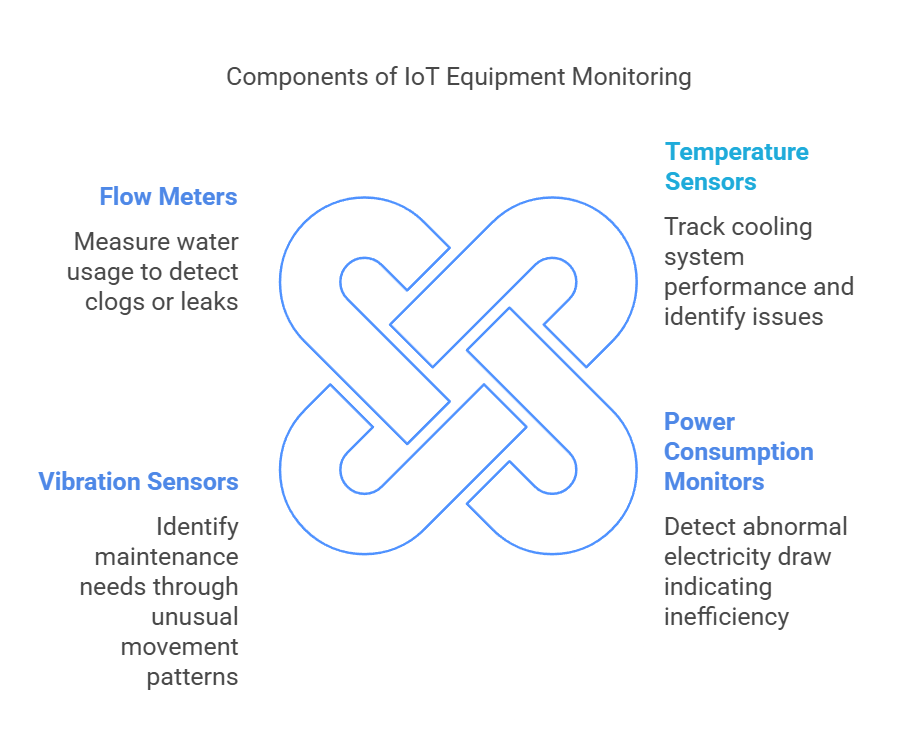

IoT sensors attached to kitchen equipment can monitor various parameters that indicate equipment health and performance. Common monitoring applications include:

- Temperature sensors in refrigeration units that track cooling system performance and may help identify developing issues with compressors or cooling systems

- Power consumption monitors that can detect when equipment draws more electricity than its baseline, which may suggest mechanical wear or inefficiency

- Vibration sensors capable of detecting unusual movement patterns in mechanical components, potentially indicating maintenance needs

- Flow meters that measure water usage in dishwashers and beverage systems, helping identify potential clogs or leaks

These sensors transmit data to a central system, working to establish baseline performance patterns. However, the accuracy and reliability of these readings depend significantly on sensor quality, proper installation, and regular calibration.

POS Integration for Operational Context

Any Point of Sale for restaurants system provides operational context that helps interpret equipment sensor data, though the usefulness of this integration varies based on the sophistication of both systems and the quality of implementation. When properly configured, this integration can help restaurants:

- Analyze how different menu items and service patterns impact equipment stress levels

- Study equipment performance during varying levels of service volume

- Evaluate seasonal impacts on equipment reliability

- Monitor equipment recovery patterns after intense usage

- Assess the operational impact of equipment inefficiencies

System Architecture for Integration

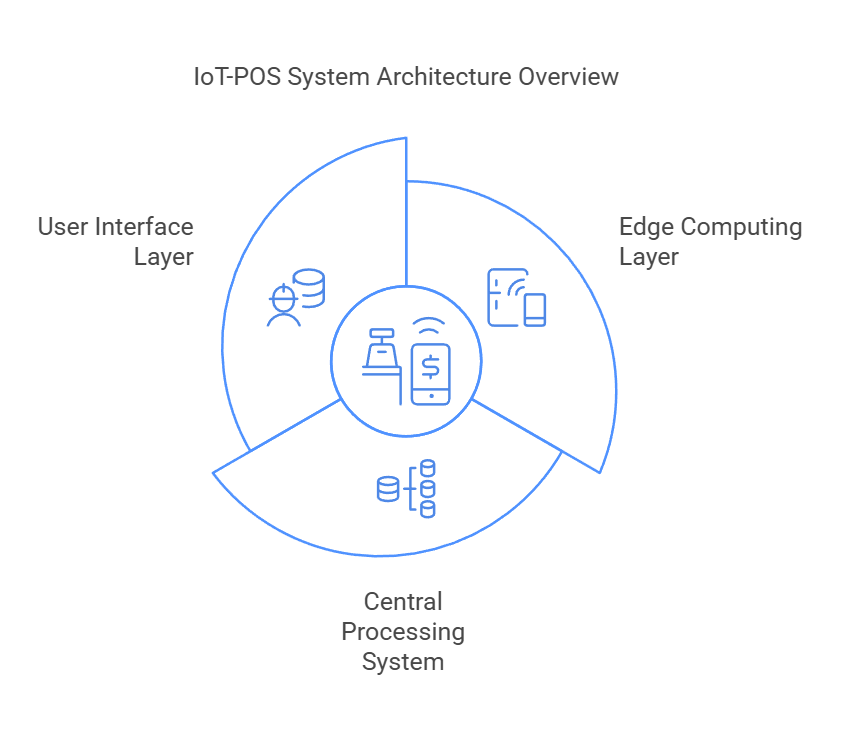

A robust IoT-POS integration requires careful attention to system architecture and component selection. Restaurants should consider working with experienced systems integrators to ensure proper setup and configuration. The core infrastructure typically includes three main layers:

The edge computing layer handles local data processing and requires careful consideration of kitchen environmental factors. This includes planning for high temperatures, humidity, and the presence of cooking oils and food particles that could affect equipment performance. Key components should include redundant network connectivity and local data storage to prevent information loss during network interruptions.

The central processing system forms the backbone of the integration, requiring specific technical components for effective operation. Common time-series databases like InfluxDB or TimescaleDB can handle the continuous stream of sensor data, while integration platforms such as MuleSoft or Apache Kafka can manage data flow between systems. API gateways like Kong or Apigee provide secure access points for external communications.

The user interface layer must balance functionality with usability, considering the varied technical expertise of restaurant staff. This typically includes monitoring dashboards, mobile alerts, and reporting tools, though the specific features should align with actual operational needs rather than implementing technology for its own sake.

Transforming Maintenance Through Connected Equipment

When kitchen equipment becomes part of an integrated IoT-POS ecosystem, restaurants gain new capabilities for maintenance and operations, though results can vary significantly based on implementation quality and operational factors.

Early Problem Detection

Connected systems can identify changes in equipment behavior that may indicate developing issues. For example:

- A commercial refrigerator showing gradually increasing power consumption might indicate developing problems, though the specific cause requires professional diagnosis

- Changes in dishwasher pump vibration patterns could suggest maintenance needs, but interpretation requires expertise

- Unusual temperature fluctuations might indicate potential issues, though environmental factors must be considered

Data-Driven Maintenance Planning

Rather than relying solely on fixed schedules, restaurants can incorporate performance data into maintenance planning. This approach considers multiple factors:

- Equipment condition indicators from sensor data

- Historical performance patterns

- Operational schedules and peak periods

- Staff availability and expertise

- Parts availability and lead times

While this approach can improve maintenance efficiency, results depend heavily on data quality and proper interpretation. Organizations should maintain some flexibility in their maintenance scheduling to account for unexpected issues or emergency repairs.

Cost Impact Analysis

The financial implications of IoT-POS integration can be significant, though outcomes vary based on multiple factors including implementation quality, existing infrastructure, and operational characteristics. Understanding these variables helps set realistic expectations for potential benefits.

Equipment Lifespan and Efficiency

Proactive maintenance based on performance data may help extend equipment life, though the actual impact varies significantly by equipment type, usage patterns, and environmental conditions. Rather than focusing on specific year estimates, restaurants should track their own equipment performance data to understand potential lifespan improvements.

Energy efficiency improvements often emerge as a measurable benefit of connected systems. Common findings include:

- Detection of refrigeration units operating inefficiently due to maintenance needs

- Identification of equipment running outside optimal performance ranges

- Recognition of excessive utility consumption patterns that may indicate maintenance requirements

However, achieving these benefits requires consistent monitoring and prompt attention to identified issues. The actual cost savings depend heavily on local utility rates, equipment condition, and the organization’s ability to act on system insights.

Multi-Location Benefits

For restaurant groups operating multiple locations with Point of Sale for restaurants systems, IoT integration provides additional opportunities through centralized monitoring and analysis, though realizing these benefits requires strong organizational coordination.

Performance Analysis

Centralized monitoring enables several key capabilities:

- Cross-location equipment performance comparison

- Identification of maintenance cost variations between locations

- Documentation and sharing of successful maintenance approaches

- Recognition of training opportunities based on equipment handling patterns

Resource Management

Connected systems can help optimize resource allocation across locations:

- More efficient scheduling of maintenance personnel

- Better coordination of spare parts inventory

- Improved planning for equipment replacement

- Enhanced sharing of technical expertise across locations

However, successful implementation requires careful attention to local variations in equipment, staffing, and operational patterns.

Implementation Strategy

A successful IoT-POS integration requires thorough planning and systematic implementation, with careful attention to both technical and operational considerations. The process typically spans several months and should include contingency planning for potential challenges.

Technical Infrastructure Foundation

Network infrastructure forms the critical backbone of any IoT implementation. Restaurants should work with qualified IT professionals to ensure their infrastructure meets both current and future needs. Key considerations include:

- Network segmentation to isolate IoT devices from other systems

- Backup internet connections with automatic failover capability

- Edge computing solutions for local data processing

- Secure connections between locations and central systems

Hardware selection must account for the harsh realities of commercial kitchen environments. Equipment considerations include moisture resistance, temperature tolerance, and protection from cleaning chemicals and food particles. While industrial-grade components cost more initially, they typically offer better reliability in kitchen environments.

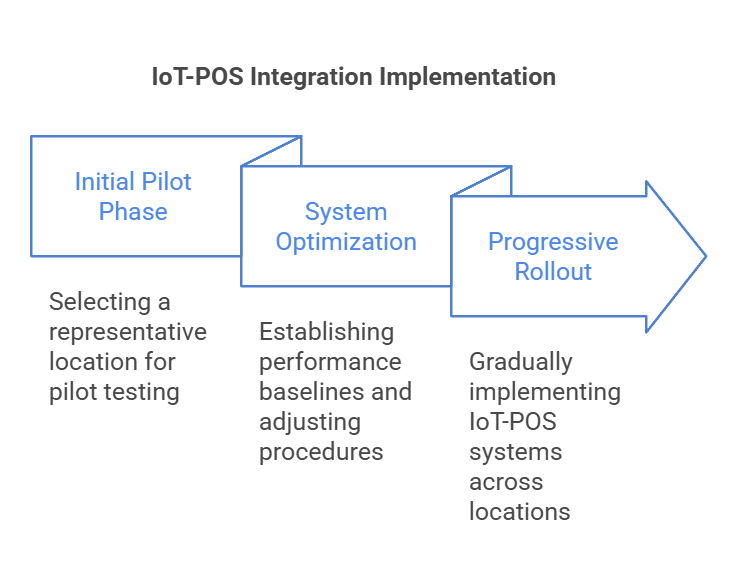

Phased Implementation Approach

A methodical, phased implementation helps identify and address issues before they affect multiple locations. The process typically follows these stages:

Initial Pilot Phase:

- Select a location that represents typical operations

- Start with critical equipment monitoring

- Document all procedures and challenges

- Gather staff feedback and adjust processes

System Optimization:

- Establish realistic performance baselines

- Adjust alert thresholds based on actual operations

- Refine maintenance procedures

- Update training materials based on pilot experience

Progressive Rollout:

- Implement at additional locations gradually

- Incorporate lessons learned from earlier installations

- Maintain flexibility for location-specific needs

- Build internal support through demonstrated benefits

Security and Compliance Integration

Security considerations must remain paramount throughout the implementation process. The connected kitchen environment requires comprehensive protection while maintaining operational efficiency. Key security elements include:

Data protection measures span several critical areas:

- Encrypted communication for all connected devices

- Regular security assessments and updates

- Controlled access based on job roles

- Secure data backup and recovery systems

Compliance requirements vary by location and must be integrated into the system design:

- Digital temperature monitoring for food safety

- Electronic maintenance record keeping

- Automated compliance reporting

- Integration with existing safety protocols

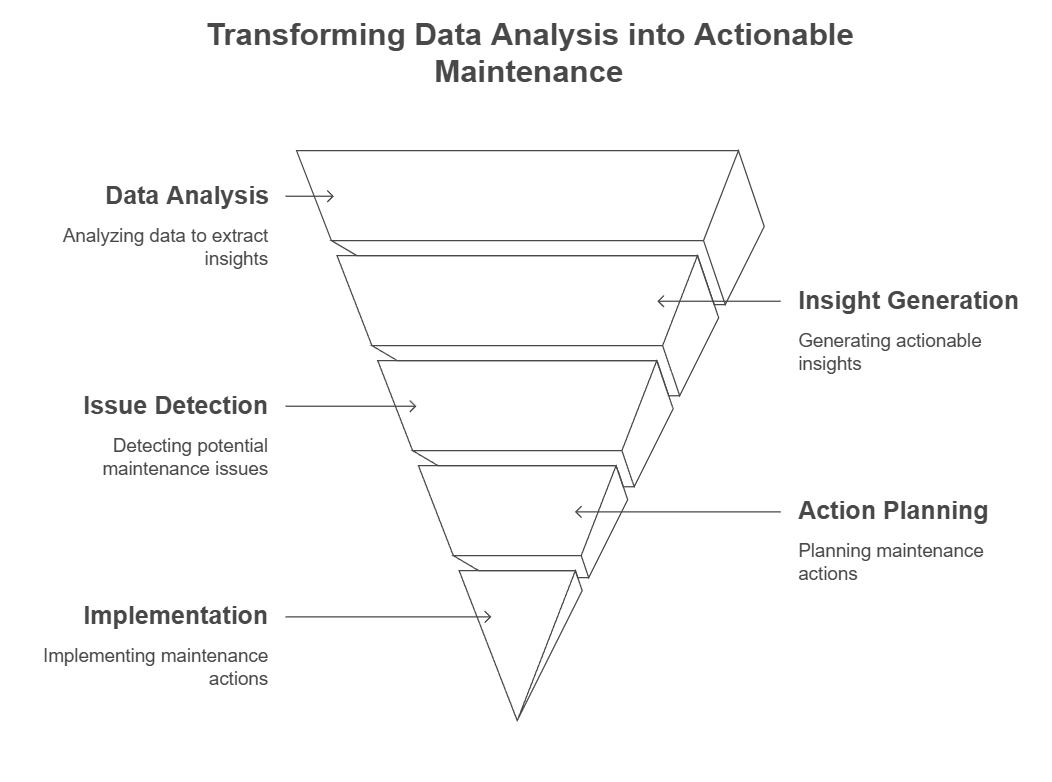

Advanced Analytics and Practical Application

The value of IoT-POS integration emerges through the practical application of collected data. While sophisticated analysis methods exist, the focus should remain on generating actionable insights that improve operations and reduce costs.

Performance Analysis Framework

Modern maintenance systems employ various analytical approaches, though the interpretation of results requires both technical understanding and operational experience. Analysis typically includes:

Equipment behavior pattern monitoring helps identify potential issues early, though proper baseline establishment is crucial. The system might detect:

- Changes in regular operating patterns

- Variations in power consumption

- Irregular temperature or performance cycles

Statistical modeling can support maintenance planning, but results should be viewed as guidance rather than absolute predictions. Common analytical approaches include:

- Trend analysis to identify gradual performance changes

- Pattern recognition to spot developing issues

- Seasonal analysis to understand cyclical impacts

Practical Implementation

Converting analysis into action requires clear procedures and consistent follow-through. A typical workflow might include:

- System detection of potential issues

- Assessment of urgency and required response

- Work order generation with available diagnostic information

- Maintenance scheduling based on business impact

- Parts ordering if needed

- Post-maintenance performance verification

Financial Considerations

While IoT integration can generate significant benefits, results vary based on multiple factors. Organizations should track several key metrics to evaluate performance:

- Emergency repair frequency and cost

- Overall maintenance expenses

- Equipment replacement frequency

- Energy consumption patterns

- Service interruption impacts

Conclusion

IoT integration with Point of Sale for restaurants systems offers restaurants new capabilities for equipment maintenance and operational optimization. While the technology shows promise, success depends on careful planning, realistic expectations, and consistent execution. Organizations should approach implementation methodically, focusing on generating practical value rather than implementing technology for its own sake.

Frequently Asked Questions (FAQ)

Q: What are the essential infrastructure requirements for implementing IoT integration in a restaurant?

A: Essential requirements include commercial-grade IoT sensors appropriate for kitchen environments, reliable primary and backup internet connectivity, secure network configuration with proper segmentation, and POS systems with integration capabilities. The specific requirements vary based on restaurant size and operational complexity.

Q: How should restaurants determine if they’re ready for IoT integration?

A: Restaurants should evaluate their current infrastructure, budget for both implementation and ongoing maintenance, staff technical capabilities, and operational needs. A technology assessment by qualified professionals can help determine readiness and identify necessary upgrades.

Q: What are the primary challenges in implementing IoT integration?

A: Common challenges include ensuring reliable connectivity in harsh kitchen environments, training staff effectively, maintaining system security, managing data quality, and coordinating between multiple vendors and systems. Success requires addressing both technical and operational considerations.

Frequently Unasked Questions (FUQ)

Q: How does IoT integration affect staff morale and retention?

A: While often overlooked, IoT integration can impact staff satisfaction in various ways. Some staff may feel more confident with better equipment monitoring, while others might need time to adapt to new procedures. Clear communication and training are essential for maintaining positive staff engagement.

Q: What are the environmental implications of implementing IoT systems?

A: IoT integration can support environmental sustainability through improved energy efficiency and reduced equipment waste. However, organizations should also consider the environmental impact of the IoT devices themselves, including their production, power consumption, and eventual disposal.

Q: How might future regulations affect restaurant IoT systems?

A: As connected systems become more common, restaurants may face new regulations regarding data security, privacy, and equipment monitoring. Organizations should design their systems with flexibility to accommodate potential regulatory changes and maintain thorough documentation of their security and compliance measures.

Power Your Restaurant with the Best Cloud-Based POS System

Take your restaurant operations to the next level with Adora POS—the industry-leading cloud-based point-of-sale system designed for pizzerias, bars, and restaurants. With enterprise management, seamless inventory tracking, and remote access, our system keeps your business running smoothly from anywhere.